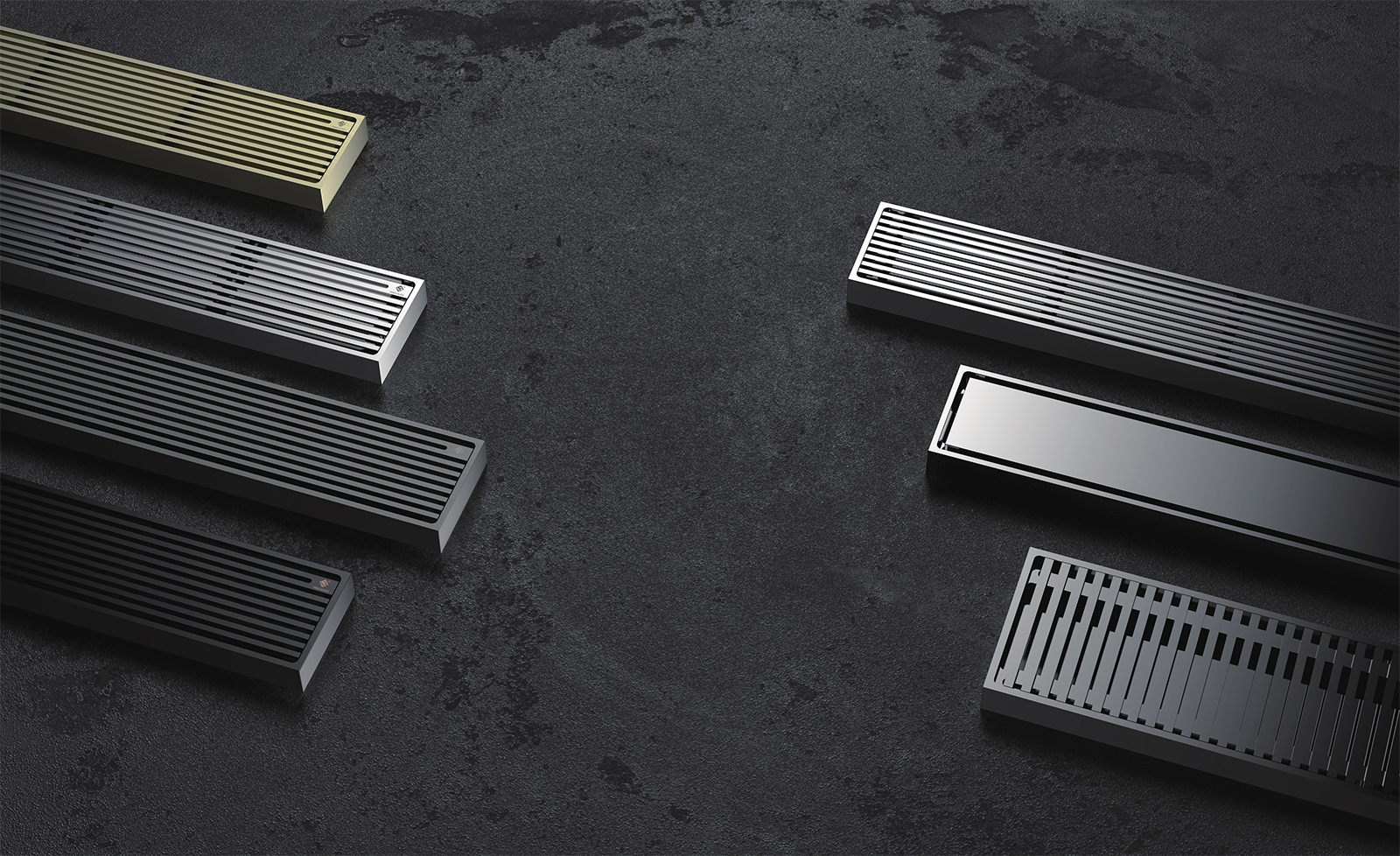

1. Khetho ea lintho tse bonahalang:sehlahisoa se sebelisa lisebelisoa tse tala tsa HPB59-1, se na le thepa e ntle ea mochini, se khona ho mamella ts'ebetso ea khatello e chesang le e batang, boima bo phahameng le polasetiki e ntle, botsitso le sebopeho se betere ho feta lihlahisoa tsa tšepe tse se nang tšepe.

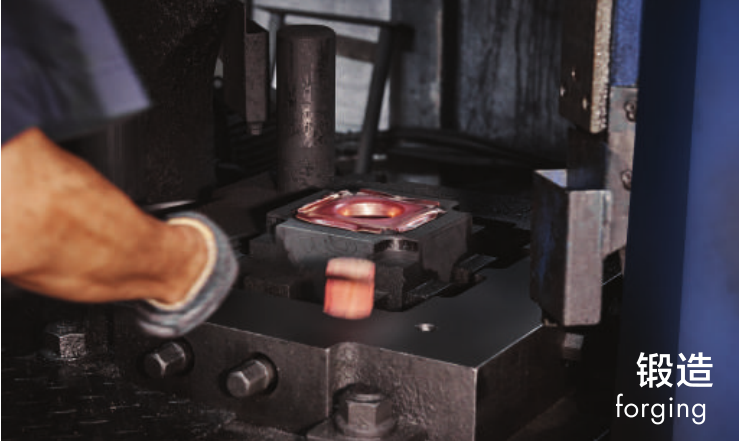

2. Ho khaola:Khaola bar ea koporo ka ingot ea koporo ka boholo bo lekanang

3. Ho qapa:Lithane tse 630 tsa CNC screw screw press (J58K-630) e sebelisoa bakeng sa ho fereka ho chesang ho se nang letho, ho theha ka nako e le 'ngoe, e le hore ho nepahala ha ho qhekella ho phahame, boima ba thepa ea likaroloana, bo tiisang letsoalo le ho tšoana ha mohaho oa fatše, oa' mele. thepa le ho hanyetsa kutu li ntlafalitsoe ka mokhoa o hlakileng, ho fihlela ho se na deformation, tšebeliso ea bophelo bohle.

4. Sebopeho:Mochini tokiso ya sehlahisoa bohale bo otlolohile kapa che.

5. Boemo bo phahameng:tlosa lintho tse tala

6. Ho thunya:tlosa oxide e holim'a metsi le litšila tse ling ho ntlafatsa boleng ba ponahalo, ho ntlafatsa fracture ea mokhathala, ho thibela ho khathala, ho senyeha ha polasetiki le ho robeha ha brittle, ho ntlafatsa bophelo ba mokhathala.

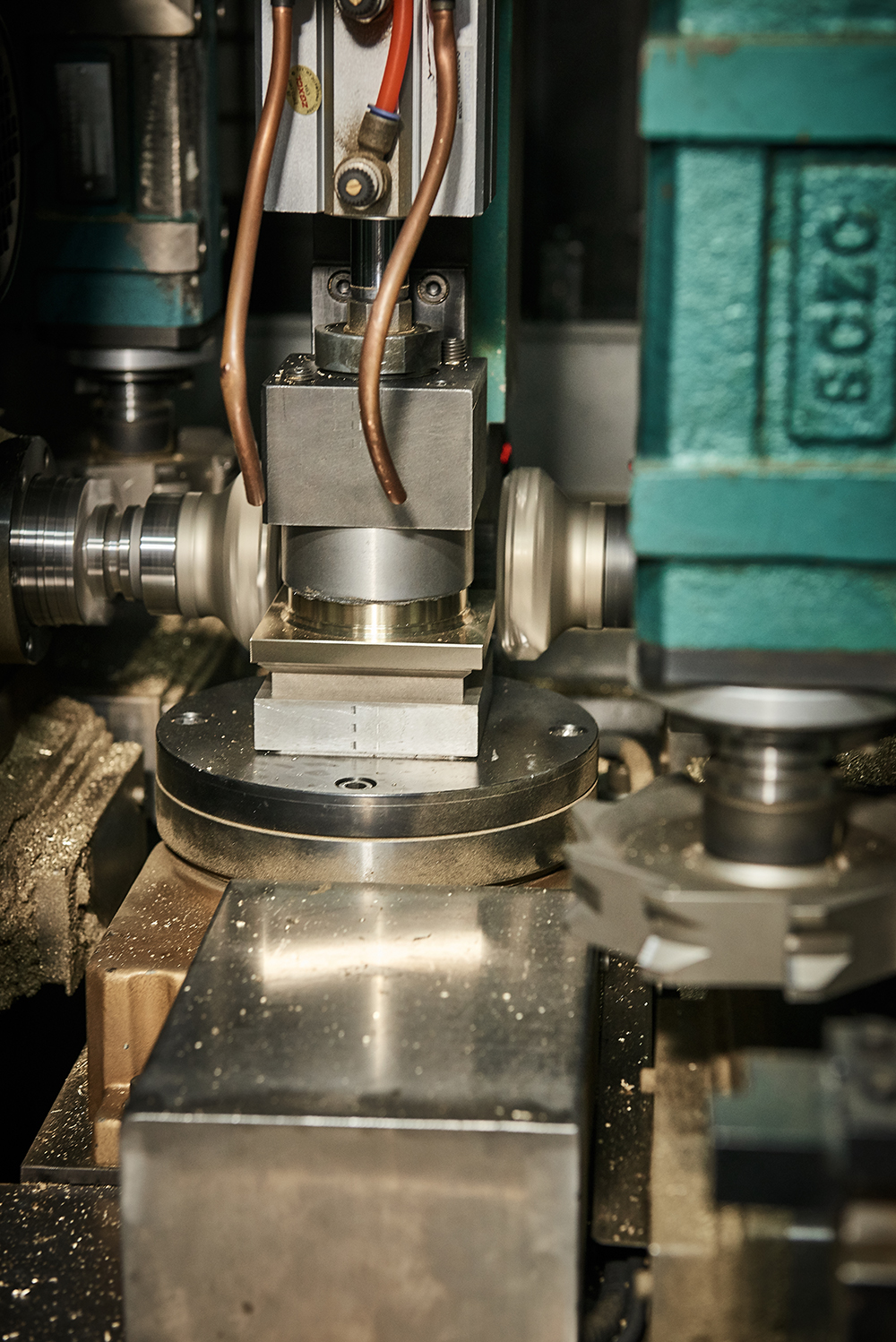

7. Ho reteleha:ho fetola lihlahisoa tse entsoeng ka ho potoloha ka sesebelisoa sa ho fetola ho netefatsa boemo bo nepahetseng ba sebaka sa machining sa lihlahisoa tse entsoeng.

8. Moeli oa ho tlatsa:sekheo se lokisoa ka ts'ebetso ea ho sila, 'me mochini o potolohang oa lebelo le phahameng o tsoela pele ho sekoa ho khaola sebopeho le likarolo tse hlokahalang.

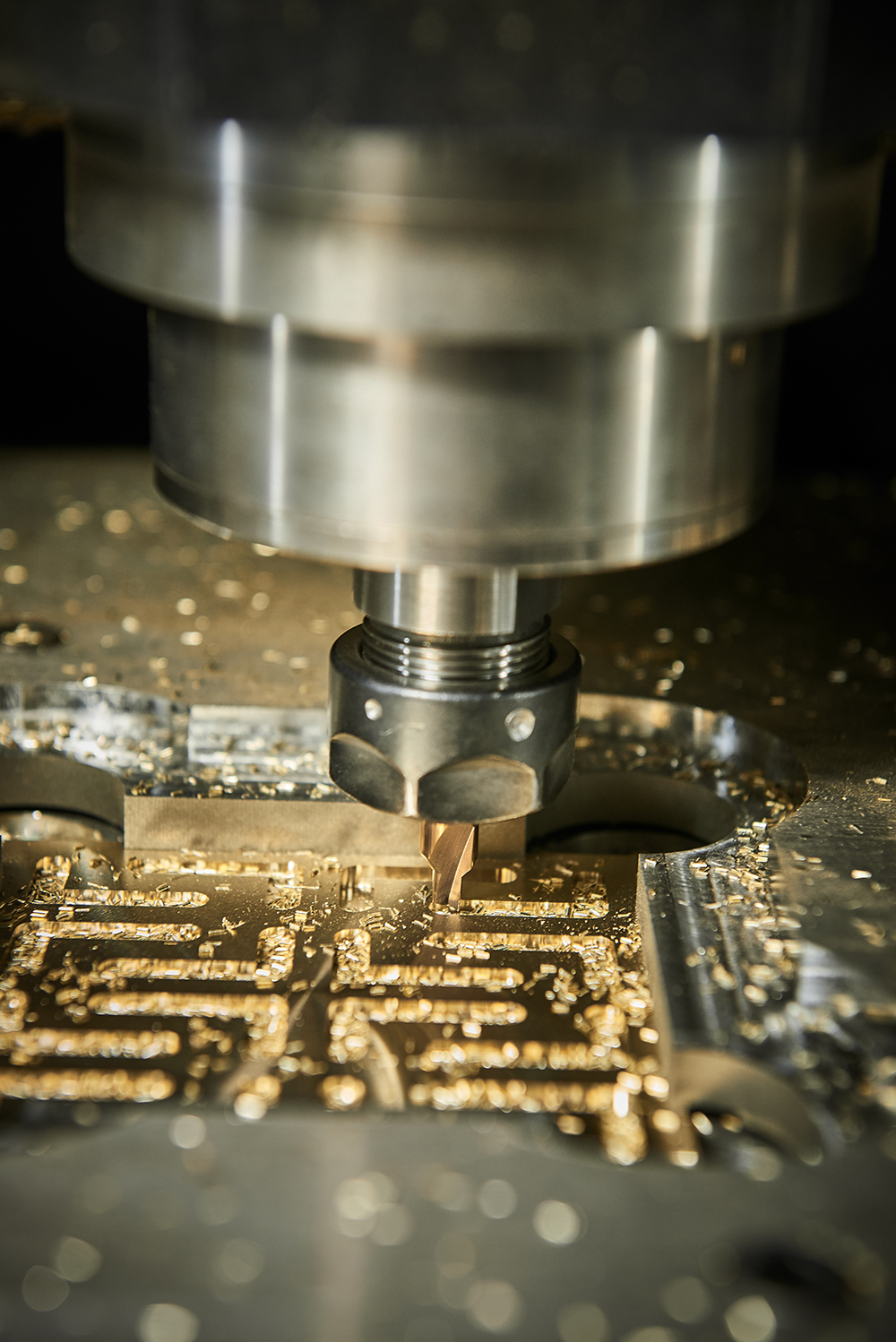

9.Ho betla leboteng ka hare:etsa hore hare-hare groove ea fatše drain 'mele ntle ntle le sakha leino, le bokaholimo bo ka tlaase boreleli le hlakileng.

10. ho betla mohlala:moralo o pota-potileng phanele, ntle le ho itšeha matsoho, moeli oa phanele o hloekisitsoe, e le hore mohlala o khabisitsoeng o na le

kutlo ya mahlakore a mararo

11. polishing:ho belisoa ha sehlahisoa ka lekhetlo la pele ka ho sila ka lebanta la abrasive ho fokotsa bokaholimo ba metsi a fatše

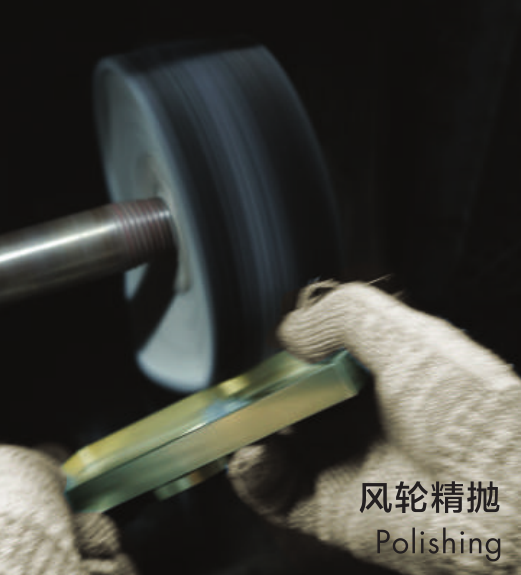

12. ho bentša ka nepo:ka moea lebili polishing ke ho fumana bokaholimo bo boreleli kapa seipone benyang ka morero, lebelo le phahameng rotating polishing lebili (circumferential lebelo la ho feta 20 m/s) khatello ea ho lihlahisoa Processed, e le hore holim abrasive ea Processed. lihlahisoa tse rolling le micro cutting, e le hore u fumane sebaka se khanyang se sebetsitsoeng, se etsa hore lintlha tsa sehlahisoa li be monate.

13. Electroplating:sehlahisoa sa electroplating grade ea 10 μ, ho latela ka tieo litlhoko tsa seipone tsa ts'ebetso e tloaelehileng, likarolo tse 5 tsa electroplating ho etsa hore sehlahisoa se benyang se be bobebe.

14. Teko ea ho fafatsa letsoai:lihlahisoa tsohle li lekoa lihora tse 24 ho se nke lehlakore setlolo sa letsoai pele se tloha fekthering

15. Tlhahlobo:ho tloha tlhahlobong ea thepa e tala, tlhahlobo e se nang letho, tlhahlobo ea ho qetela, tlhahlobo ea ho bentša, tlhahlobo ea ho roala, tlhahlobo ea ho qetela ho netefatsa hore sehlahisoa se sebetsa hantle.

16. Ho tšoaea:Letšoao la Laser, mongolo oa laser, lets'oao le khahlanong le ho qhekella, tiisetso ea 'nete, ka kopo batla lets'oao la tlhoro la FENGCAI

17. Ho paka:matla a phahameng le pampiri e tenya e tsoang kantle ho naha, e tenyetsehang ebile e matla

Litakatso tsa k'hamphani

Khetho ea kamore ea ho hlapela, khetho ea ntlo, khetho ea malapa a limilione ha ho letho leo u ka le tšepang, empa ho etsa hantle.

Mosebetsi oa khoebo

Re ikemiselitse ho fa bareki litharollo tse ntle ka ho fetisisa tsa bophelo bo botle ba likhoerekhoere le ho ba bafani ba lits'ebeletso tsa boemo ba lefats'e tsa ho tsamaisa metsi

Nako ea poso: Apr-07-2022